Standard Products

CLI JF Series Cylindrical Bimetal Bushings (Metric Size in mm) |

CLI No. | Φd | ΦD | L | ΦH |

| CLI 1010 | 10 | 12 | 10 | 4 |

| CLI 1015 | 15 |

| CLI 1020 | 20 |

| CLI 1210 | 12 | 10 |

| CLI 1215 | 15 |

| CLI 1220 | 20 |

| CLI 1225 | 25 |

| CLI 1410 | 14 | 16 | 10 |

| CLI 1415 | 15 |

| CLI 1420 | 20 |

| CLI 1425 | 25 |

| CLI 1510 | 15 | 17 | 10 |

| CLI 1515 | 15 |

| CLI 1520 | 20 |

| CLI 1525 | 25 |

| CLI 1610 | 16 | 18 | 10 |

| CLI 1615 | 15 |

| CLI 1620 | 20 |

| CLI 1625 | 25 |

| CLI 1815 | 18 | 20 | 15 |

| CLI 1820 | 20 |

| CLI 1825 | 25 |

| CLI 2010 | 20 | 23 | 10 |

| CLI 2015 | 15 |

| CLI 2020 | 20 |

| CLI 2025 | 25 |

| CLI 2030 | 30 |

| CLI 2215 | 22 | 25 | 15 | 6 |

| CLI 2220 | 20 |

| CLI 2225 | 25 |

| CLI 2230 | 30 |

| CLI 2515 | 25 | 28 | 15 |

| CLI 2520 | 20 |

| CLI 2525 | 25 |

| CLI 2530 | 30 |

| CLI 2815 | 28 | 32 | 15 |

| CLI 2820 | 20 |

| CLI 2825 | 25 |

| CLI 2830 | 30 |

| CLI 3015 | 30 | 34 | 15 |

| CLI 3020 | 20 |

| CLI 3025 | 25 |

| CLI 3030 | 30 |

| CLI 3040 | 40 |

| CLI 3220 | 32 | 36 | 20 |

| CLI 3230 | 30 |

| CLI 3240 | 40 |

| CLI 3520 | 35 | 39 | 20 |

| CLI 3530 | 30 |

| CLI 3535 | 35 |

| CLI 3540 | 40 |

| CLI 3550 | 50 |

| CLI 4020 | 40 | 44 | 20 | 8 |

| CLI 4030 | 30 |

| CLI 4040 | 40 |

| CLI 4050 | 50 |

| CLI 4530 | 45 | 50 | 30 |

| CLI 4540 | 40 |

| CLI 4545 | 45 |

| CLI 4550 | 50 |

| CLI 5030 | 50 | 55 | 30 |

| CLI 5040 | 40 |

| CLI 5050 | 50 |

| CLI 5060 | 60 |

| CLI 5540 | 55 | 60 | 40 |

| CLI 5550 | 50 |

| CLI 5560 | 60 |

| CLI 6030 | 60 | 65 | 30 |

| CLI 6040 | 40 |

| CLI 6060 | 60 |

| CLI 6530 | 65 | 70 | 30 |

| CLI 6550 | 50 |

| CLI 6570 | 70 |

| CLI 7040 | 70 | 75 | 40 |

| CLI 7050 | 50 |

| CLI 7070 | 70 |

| CLI 7560 | 75 | 80 | 60 | 9.5 |

| CLI 7580 | 80 |

| CLI 8060 | 80 | 85 | 60 |

| CLI 80100 | 100 |

| CLI 8530 | 85 | 90 | 30 |

| CLI 8560 | 60 |

| CLI 85100 | 100 |

| CLI 9060 | 90 | 95 | 60 |

| CLI 90100 | 100 |

| CLI 9560 | 95 | 100 | 60 |

| CLI 95100 | 100 |

| CLI 10060 | 100 | 105 | 60 |

| CLI 100115 | 115 |

| CLI 10560 | 105 | 110 | 60 |

| CLI 105115 | 115 |

| CLI 11060 | 110 | 115 | 60 |

| CLI 110115 | 115 |

| CLI 11550 | 115 | 120 | 50 |

| CLI 11570 | 70 |

| CLI 12050 | 120 | 125 | 50 |

| CLI 12060 | 60 |

| CLI 120110 | 100 |

| CLI 125100 | 125 | 130 | 100 |

| CLI 13060 | 130 | 135 | 60 |

| CLI 130100 | 100 |

| CLI 13560 | 135 | 140 | 60 |

| CLI 13580 | 80 |

| CLI 14060 | 140 | 145 | 60 |

| CLI 140100 | 100 |

| CLI 15060 | 145 | 150 | 60 |

| CLI 15080 | 80 |

| CLI 150100 | 100 |

| Standard Products

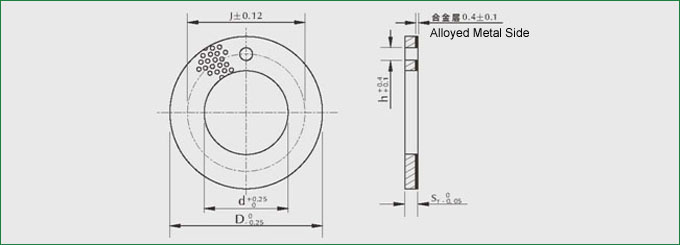

CLI JF Series Bimetal Washers (Metric Size in mm) |

| CLI No. | Φd +0.25 0 | ΦD 0 - 0.25 | ST 0 - 0. 05 | ΦJ±0.12 | Φh +0.4 +0.1 |

| CLI W 10 | 12 | 24 | 1.5 | 18 | 1.5 |

| CLI W 12 | 14 | 26 | 20 | 2 |

| CLI W 14 | 16 | 30 | 22 |

| CLI W 16 | 18 | 32 | 25 |

| CLI W 18 | 20 | 36 | 28 | 3 |

| CLI W 20 | 22 | 38 | 30 |

| CLI W 22 | 24 | 42 | 33 |

| CLI W 24 | 26 | 44 | 35 |

| CLI W 25 | 28 | 48 | 38 | 4 |

| CLI W 30 | 32 | 54 | 43 |

| CLI W 35 | 38 | 62 | 50 |

| CLI W 40 | 42 | 6.6 | 54 |

| CLI W 45 | 48 | 74 | 2 | 61 |

| CLI W 50 | 52 | 78 | 65 |

| Standard Products

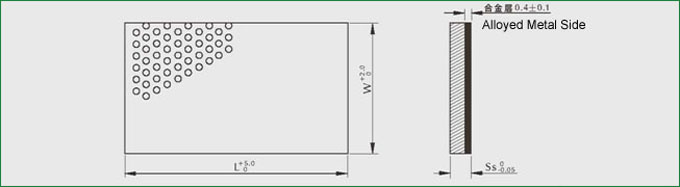

CLI JF Series Bimetal Plates (Metric Size in mm) |

| CLI No. | L +5.0 0 | W+2.0 0 | Ss 0 -0.05 |

| CLI p 100125 | 500 | 125 | 1.0 |

| CLI p 150125 | 1.5 |

| CLI p 200125 | 2.0 |

| CLI p 250125 | 2.5 |

■ Chemical Composition (%) for Materials

| CLI No. | Material Code | Hardness | Same Materials |

| CLI-JF800 | CuPb10Sn10 | 60-90 HB | SAE-797, DIN CuPb10Sn, JIS-LBC3, Daido L10, Federal Mogul HF2, Glacier SY, GLYCO 66, ACL F100 |

| CLI-JF850 | CuPb24Sn | 45-70HB | SAE-799, GLYCO68, JIS-LBC6, Daido L23, Glacier SX, ACL F250 |

| CLI-JF720 | CuPb24Sn4 | 40-60HB | SAE-49, ACL F780 |

| CLI-JF820 | ALSn20Cu | 30-40HB | SAE-783, GLYCO74, JIS-AJL, Glacier As15, ACL 820 |

| CLI-JF700 | CuPb30 | 30-45HB | SAE-48, JIS-KJ3, Glacier SL |

■ Chemical Composition (%) of Materials

| Chemicals | CLI-JF800

CuPb10Sn10 | CLI-JF720

CuPb24Sn4 | CLI-JF850

CuPb24Sn | CLI-JF820

ALSn20Cu | CLI-JF700

CuPb30 |

| Cu | Rest | Rest | Rest | 0.7~1.3 | Rest |

| Pb | 9~11 | 19~27 | 19~27 | - | 26~33 |

| Sn | 9~11 | 3~4.5 | 0.6~2 | 17.5~22.5 | 0.5 |

| Zn | 0.5 | 0.5 | 0.5 | - | 0.5 |

| P | 0.1 | 0.1 | 0.1 | - | 0.1 |

| Fe | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 |

| Ni | 0.5 | 0.5 | 0.5 | 0.1 | 0.5 |

| Sb | 0.2 | 0.2 | 0.2 | - | 0.2 |

| AL | - | - | - | Rest | - |

| Si | - | - | - | 0.7 | - |

| Mn | - | - | - | 0.7 | - |

| Ti | - | - | - | 0.2 | - |

| Others | 0.5 | 0.5 | 0.5 | 0.5 | 0.5

|

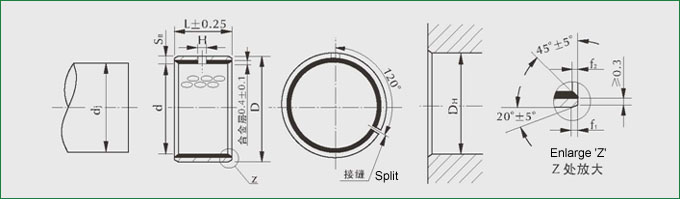

■ Bush Tolerance of ID, OD, Shaft Diameter and Housing Diameter

| Basic Dimensions

mm | O.D.

mm | I.D.

mm | Housing Dia

DH | Shaft Dia

dj |

| 10~18 | +0.065 +0.035 | +0.043 0 | +0.018 0 | -0.016 -0.034 |

| 18~30 | +0.075 +0.035 | +0.052 0 | +0.021 0 | -0.020 -0.041 |

| 30~50 | +0.085 +0.045 | +0.062 0 | +0.025 0 | -0.025 -0.050 |

| 50~80 | +0.100 +0.055 | +0.074 0 | +0.030 0 | -0.030 -0.060 |

| 80~120 | +0.12 +0.07 | +0.087 0 | +0.035 0 | -0.036 -0.071 |

| 120~180 | +0.17 +0.10 | +0.10 0 | +0.040 0 | -0.043 -0.083 |

■ Tolerance of bush’s wall thickness & Chamfer

| Basic Dimensions

φd | Wall Thickness

SB | Chamfer |

| f1 | f2 |

| 8~18 | 1 0 -0.04 | 0.6±0.4 | max 0.4 |

| 18~25 | 1.5 0 -0.045 | 0.6±0.4 | 0.4±0.3 |

| 25~40 | 2 0 -0.05 | 1.2±0.4 | 0.4±0.3 |

| 40~150 | 2.5 0 -0.06 | 1.8±0.4 | 0.6±0.4 |

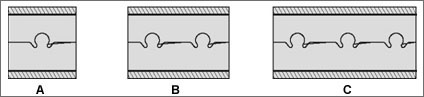

■ Typical split-connections |

| ■ Typical oil grooves & pockets |