Bearing Installation

Bushes

|

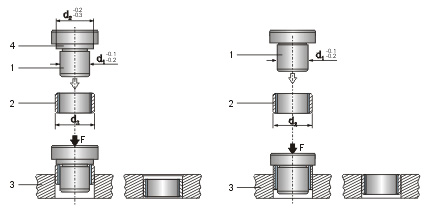

1.Pressing-in arbor

2.Bushes

3.Housing

4.Shoulder diameter

|

In most cases, CLI sliding bearing are used with a pressfit in the same manner as general sleeve bearings. Fit the bearings into housings using mandrels or press. In case of a relatively large interference, provide both the I.D. Of the housing and the O.D. Of bearing with chamfers, and fit the bearing into the housing with mandrel for easy installation. When using plastic bearing in an environment where temperature fluctuates, install the bearing using set screws, keys or flange pins for better results.

For some special application like CLI650# bushes for injection molding machines, can be used shrink fitting. This is the preferred method of inserting a bush in its housing and provides the optimum interference fit without risking bearing damage during press fitting. Forzen carbon dioxide(co2) should be packed around the bearing for up to 2 hours, depending on the cross section of bush to be cooled. Once removed from the co2, the bush should be offered to its housing without delay. It should fit without force, gravity will usually be adequate for a vertical installation.

|

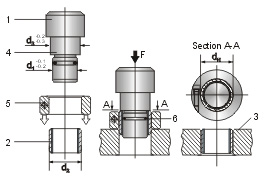

1.Pressing-in arbor

2.Bushes

3.Housing

4.Shoulder diameter

5.Auxiliary ring

6.O ring

|

d2mm

|

dHmm

|

|

50<d2Ý¡100

|

d2

|

0.28

|

|

0.25

|

|

100<d2Ü¡200

|

d2

|

0.4

|

|

0.36

|

|

200<d2Ü¡305

|

d2

|

0.5

|

|

0.46

|

|

At the on-start of operation, contact surfaces of shaft and bearings are smooth, however, microscopic irregularities are inevitable to develop after continued use. A deviation from true center alignment may also exist. Thus, the initial contact between sliding surface could be local. Do not immediately start a regular loaded operation, it may result in damaging the gearing surface, leading to a shorter service life. Instead, gradually break-in operations so to smooth out the microscopic irregularities, and allow the entire pressure support area to slowly come in contact without causing damage.

Storage

CLI slide bearings are supplied packed in boxes or in a bag in a box. The bearings should be stored in clean, rust proof manner. The thin wall bearings like EP should be protected from deformation during storage. Do not store in locations exposed to high temperatures, high humidity, or the direct rays of the sun, and do not place under a heavy load also.

Thrust washers and plate

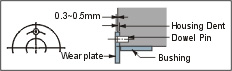

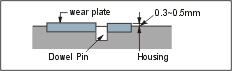

We recommended to provide housing with hollowed dents for installing thrust washers and sliding plates. Dowel pins should be applied to prevent turning.

1. Dowel pin application(thrust washer)

2. Inlaid installation(plate)

2. Inlaid installation(plate)

3. Flat head screw application

3. Flat head screw application

Alternative fixing methods

Laser welding, adhesive fixing or soft soldering have also been used for economical alternative fixing if the interference fit on the bush is not sufficient or it is uneconomical to use dowel pins or screws for trust washer and plate. When using laser welding or other higher temperature manners should be considering not exceed the max. slide layer temp. Can be bear. The sliding layer must always be kept free from adhesives.