|

|

Quality Control

Bushing Test

The wrapped or thin wall bushes are not accurately mensurable in the unfitted condition. Here we list the standard measurement method.

To test the outer diameter

The outer diameter of CLI wrapped plain bearings that have to have the interference fit (press fit) in the housing are tested with the aid of a special device.

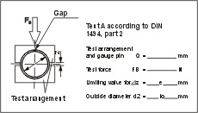

In this test the outer diameter is measured under prestressing force according to DIN 1494, part 2, test A to determine the deviation Delta Z from a standard value. Test load and permissible deviation are calculated according to DIN 1494.

Normally this method is suitable for large series.

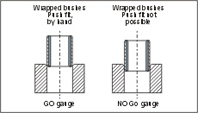

The simplified method for testing the outside diameter of plain bearings is based on DIN 1494 Method B. The test uses GO and NO GO ring gauge. The corresponding diameters of the GO and NO GO ring gauges are selected according to the DIN standard.

Normally this method is suitable for smaller series.

To test the inner diameter

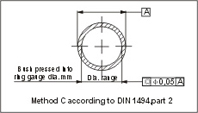

The inner diameter is tested according to DIN1494, part 2, test C. To perform this test, the bushes should be fixed in a ring gauge (table 5 according to DIN1494 part 1) in this condition the inside diameter can be tested with GO or NO GO plug gauges.

Normally this method is suitable for smaller series. The big size bushes recommend use of a three-point micrometer is preferable.

Washer Test

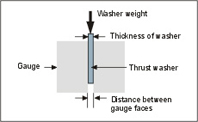

Beside the thickness, the flatness of a washer is of particular importance as it has impact on the life of both the washer and its mate.

We use very helpful test in which the washer falls through the gap between two plain parallel plates of a gauge under its dead weight. The plates must be big enough to cover the whole washer.

|

|

CLI Industrial Co., Ltd 2008. ® All Rights Reserved Friend Links: Ball Bearing

|

|