|

|

www.cli-industrial.com |

|

sales@cli-industrial.com |

|

0086 028 8669 3910 |

|

0086 028 8625 0130 |

|

Casting Bronze Bearings

■ CLI Casting Bronze Bushings / Casting Copper (Alloy) Bushing

It is based on the copper alloy. This kind of bushings are widely used in machine-tool, agricultural machinery, crane electromotor, spring pin, steering shaft and transmission, etc. Machined Cast bronze bearings offer technically and economically favorable bearings solutions. Casting bronze bushings are of high loading capability, low weight, good corrosion resistance. CLI can offer different type bronze alloys according to the life time, service etc.

■ Basic Metal Materials

The materials are based on the copper alloy. This kind of bushings are widely used in machine-tool, agricultural machinery, crane electromotor, spring pin, steering shaft and transmission, etc.

| Aluminum Bronze Bushing |  | | Material Code | International Code | Chemical Composition | Typical Properties | Typical Application | | C63000 | CuAl10Ni5Fe4

DIN.2.0966

DIN17665

CA104

CW308G | Al: 8.50-11.00%

Fe: 2.00-5.00%

Ni: 4.00-6.00%

Mn: 1.50% Max.

Sn: 0.20% Max.

Zn: 0.30% Max.

Cu: Balance | Specific Gravity: 7.58 g/cm3

Coefficient of Thermal Expansion per °C: 16.20 x 10-6 (20-300°C)

Electrical Conductivity (% IACS): 7% @ 68 F

Thermal Conductivity: 22.60 Btu · ft/(hr · ft2·oF)at 68F

Modulus of Elasticity in tension: 17500 ksi | Industrial: Hydraulic Bushings for Earth Moving Equipment;

Corrosion Resistant Articles, Bushings, Bearings. | | C95400 | CuAl11Fe4, DIN.2.0940

DIN.2.0981 | Al: 10.0-11.50%

Fe: 3.00-5.00%

Ni: 1.50%

Mn: 0.50% Max.

Cu: Balance | Specific Gravity: 7.45 g/cm3

Coefficient of Thermal Expansion per °C: 16.20 x 10-6 (20-300°C)

Electrical Conductivity (% IACS): 13% @ 68 F

Thermal Conductivity: 33.90 Btu · ft/(hr · ft2·oF)at 68F

Modulus of Elasticity in tension: 15500 ksi. | Industrial: Bearings, Bearing Segments for the Steel Industry, High Strength Clamps, Bushings…

Automotive: Weld Guns | | C62400 | CuAl11Fe3, DIN.2.0936, CA106 | Al: 10.00-11.50%

Fe: 2.00-4.50%

Mn: 0.30% Max.

Si: 0.25% Max.

Sn: 0.20% Max.

Cu: Balance | Specific Gravity: 7.45 g/cm3

Coefficient of Thermal Expansion per °C: 16.20 x 10-6 (20-300°C)

Electrical Conductivity (% IACS): 12 % @ 68 F

Thermal Conductivity: 34.0 Btu · ft/(hr · ft2·oF)at 68F

Modulus of Elasticity in tension: 17000 ksi | Industrial: Support Bushings, Hydraulic Bushings, Bushings | | C62300 | CuAl9Fe3, DIN.2.0936, CW306G

CA106 | Al: 8.50-10.00%

Fe: 2.00-4.00%

Mn: 0.50% Max.

Ni: 1.00% Max.

Si: 0.25% Max.

Sn: 0.60% Max.

Cu: Balance | Specific Gravity: 7.70 g/cm3

Coefficient of Thermal Expansion per °C: 16.20 x 10-6 (20-300°C)

Electrical Conductivity (% IACS): 12 % @ 68 F

Thermal Conductivity: 31.0 Btu · ft/(hr · ft2·oF)at 68F

Modulus of Elasticity in tension: 17000 ksi | Industrial: Bushings, Bearing retainer Cages, Bearing Races, sleeve bearings

Marine: Marine Hardware | | Phosphor Bronze Bushing |  | | Material Code | International Code | Chemical Composition | Typical Properties | Typical Application | | C51100 | CuSn4

JIS C5111

CW 450 K

PB 101 | Sn: 3.50-4.90%

P: 0.03-0.35%

Zn: 0.30% Max.

Fe: 0.10% Max.

Pb: 0.05% Max.

Cu: Balance | Specific Gravity: 8.86 g/cm3

Coefficient of Thermal Expansion per °C: 17.80 x 10-6 (20-300°C)

Electrical Conductivity (% IACS): 20% @ 68 F

Thermal Conductivity: 48.00 Btu · ft/(hr · ft2·oF)at 68F

Modulus of Elasticity in tension: 16000 ksi | Architecture: Bridge Bearing Plates

Industrial: Textile Machinery parts, Sleeve Bushings | | C51000 | CuSn5

JIS C5102

CW 451 K

PB 102 | Sn: 4.50-5.50%

P: 0.03-0.35%

Zn: 0.30% Max.

Fe: 0.10% Max.

Pb: 0.05% Max.

Cu: Balance | Specific Gravity: 8.86 g/cm3

Coefficient of Thermal Expansion per °C: 17.80 x 10-6 (20-300°C)

Electrical Conductivity (% IACS): 15% @ 68 F

Thermal Conductivity: 40.00 Btu · ft/(hr · ft2·oF)at 68F

Modulus of Elasticity in tension: 16000 ksi | Architecture: Bridge Bearing Plates

Industrial: Textile Machinery, Sleeve Bushings. | | C51900 | CuSn6

JIS C5191

CW 452 K

PB 103 | Sn: 5.50-7.00%

P: 0.03-0.35%

Zn: 0.30% Max.

Fe: 0.10% Max.

Pb: 0.05% Max.

Cu: Balance | Specific Gravity: 8.80 g/cm3

Coefficient of Thermal Expansion per °C: 18.50 x 10-6 (20-300°C)

Electrical Conductivity (% IACS): 15.50 % @ 68 F

Thermal Conductivity: 38.00 Btu · ft/(hr · ft2·oF)at 68F

Modulus of Elasticity in tension: 16000 ksi | Industrial: Textile Machinery, Sleeve Bushings | | C52100 | CuSn6

JIS C5210

CW 453 K

PB 104 | Sn: 7.50-8.50%

P: 0.03-0.35%

Zn: 0.20% Max.

Fe: 0.10% Max.

Pb: 0.05% Max.

Cu: Balance | Specific Gravity: 8.80 g/cm3

Coefficient of Thermal Expansion per °C: 18.20 x 10-6 (20-300°C)

Electrical Conductivity (% IACS): 13.00 % @ 68 F

Thermal Conductivity: 36.00 Btu · ft/(hr · ft2·oF)at 68F

Modulus of Elasticity in tension: 16000 ksi | Architecture: Bridge Bearing Plates

Marine: Marine Parts

Industrial: Automotives, Slide Bearings, Thrust Bearings, Textile Machinery | | C54400 | CuSn4Zn4Pb4

JIS H3270

EN 12164

CW 456 K | Sn: 3.50-4.50%

Pb: 3.50-4.50%

Zn: 3.50-4.50%

P: 0.01-0.50%

Fe: 0.10% Max.

Cu: Balance | Specific Gravity: 8.89 g/cm3

Coefficient of Thermal Expansion per °C: 17.30 x 10-6 (20-300°C)

Electrical Conductivity (% IACS): 19.00 % @ 68 F

Thermal Conductivity: 50.00 Btu · ft/(hr · ft2·oF)at 68F

Modulus of Elasticity in tension: 15000 ksi | Industrial: Bushings, Sleeve Bearings, Thrust Bearings, Screw Machine Products, Bearings, Thrust Washers

Marine: Marine Parts | | Silicon Bronze Bushing |  | | Material Code | International Code | Chemical Composition | Typical Properties | Typical Application | | C65500 | CuSi3Mn1

DIN 13347 DIN 14640, CW116C to EN | Si: 2.80-3.80%

Mn: 0.50-1.30%

Fe: 0.80% Max.

Zn: 1.50% Max.

Pb: 0.05% Max.

Cu: Balance | Specific Gravity: 8.53 g/cm3

Coefficient of Thermal Expansion per °C: 18 x 10-6 (20-100°C)

Electrical Conductivity (% IACS): 7 % @ 68 F

Thermal Conductivity: 21.0.0 Btu · ft/(hr · ft2·oF)at 68F

Modulus of Elasticity in tension: 15000 ksi | Industrial: Bearing Plates, Bushings, Piston Rings | | Beryllium Copper Bushing |  | | Material Code | International Code | Chemical Composition | Typical Properties | Typical Application | | C17200 | CuBe2, DIN 2.1247 CW101C to EN | Be: 1.85-2.10%

Co+Ni: 0.20% Min.

Co+Ni+Fe: 0.60% Max.

Cu: Balance | Density (g/cm3): 8.36

Density before age hardening (g/cm3): 8.25

Elastic Modulus (kg/mm2 (103)): 13.40

Thermal Expansion Coefficient (20 °C to 200 °C m/m/°C): 17 x 10-6

Thermal Conductivity (cal/(cm-s-°C)): 0.25

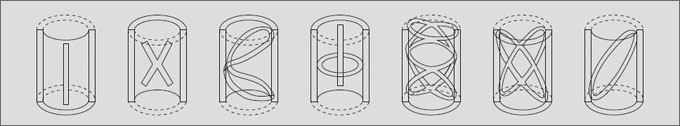

Melting Range (°C): 870-980 | Industrial: Bearings, Bushings on Heavy Load Equipment | ■ Oil holes & Oil Grooves ( DIN1591/ISO12128)

CLI Industrial Co., Ltd 2008. ® All Rights Reserved

|

|